Tips To Get Large Amount On A Coconut Shell Charcoal Making Machine

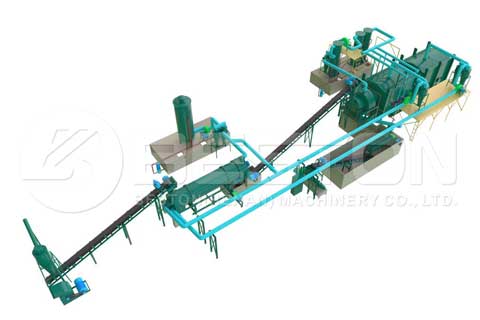

After coconuts are harvested, the shells are often discarded, resulting in several unnecessary waste. Can you imagine if these shells could possibly be turned into a usable product? That is precisely what a coconut shell charcoal production

machine allows you to do.

These machines are created to turn old coconut shells into usable charcoal. The resulting charcoal can be used anything from barbecuing to enhancing the caliber of soil for growing. It may also be used being a fuel source and can also be used in the making of some kinds of bricks. Because of so many different uses, it is easy to observe that there is a constant need for the charcoal made by these appliances.

Getting a whole lot on a charcoal making machine is not hard providing you are likely to research prices. You can often find these machines listed for incredible prices, allowing you to receive the equipment you need for your business without exceeding your financial allowance at the same time. The low you can preserve your equipment costs, the easier it will likely be for you to turn a return.

One of the better ways to spend less is actually by shopping on the web. Once you purchase equipment online, you will have a possiblity to compare options from a variety of suppliers located around the world. Getting price quotes is simple, too. Usually, all you have to do is email an organization or contact them using a special form on their website. Within almost no time, they should go back to you with a long list of prices for the machines that they sell that you are interested in.

Wanna get coconut shell charcoal briquettes

, click it right now.

You need to get quotes from as much different manufacturers and suppliers as is possible. When obtaining quotes, be sure to enquire about extra fees that you may possibly be responsible for covering. This consists of fees like taxes, shipping costs, and import fees. Adding most of these fees in is vital in order to obtain a true feeling of what a particular charcoal making machine will surely cost. Having this information will even make it easier so that you can select which company supplies the best all-around price.

If you are lucky, you might be able to invest in a used charcoal making machine, also. This is an excellent way to save money. Take into account, however, that it could be a bit tricky to discover used machines available for sale.

You might want to spend considerable time searching before you select one which is located close to where you are and that is in great shape. As with all used equipment, you need to carefully measure the machine before buying it

to be sure that it doesn't possess any problems that would prevent it from operating correctly.

They are just a couple of the ways that one could begin getting a whole lot on the coconut shell charcoal making machine. These innovative machines enable you to turn old, discarded coconut shells right into a usable, sought-after product.