By Cathy Wang

•

December 10, 2025

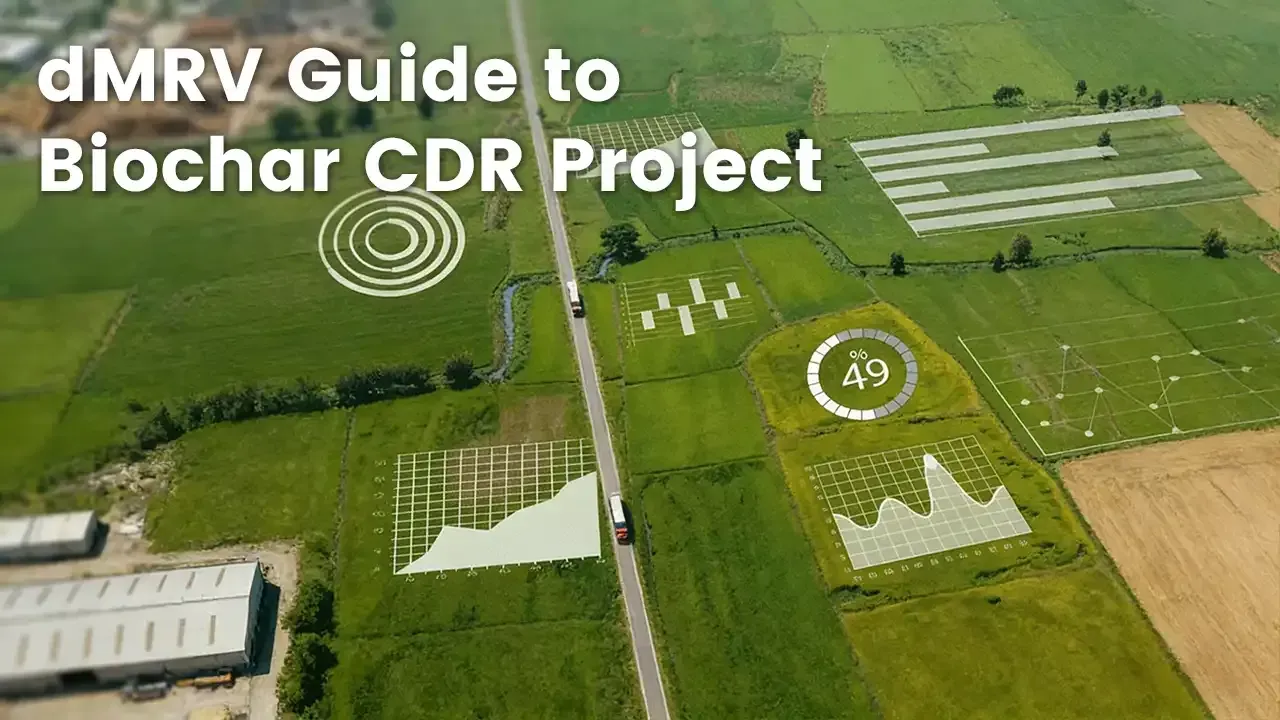

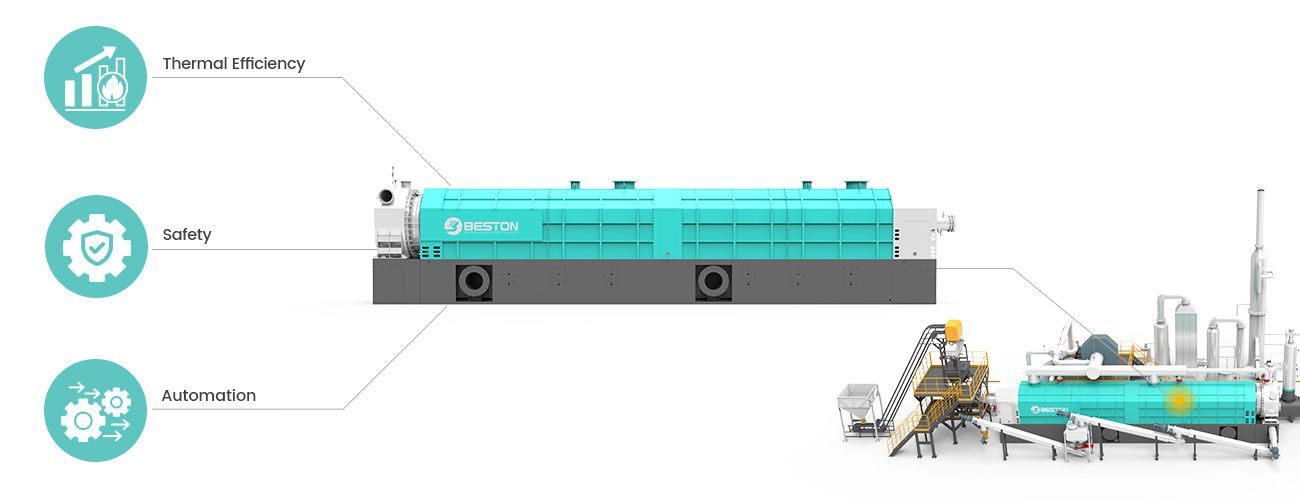

Digital measurement, reporting, and verification (dMRV) has become a central scaffold for ensuring credibility in carbon dioxide removal (CDR) pathways. Biochar projects, particularly those operating through a pyrolysis plant, rely on rigorous instrumentation and well-structured data methodologies to substantiate their climate claims. dMRV provides an auditable, transparent mechanism for quantifying carbon flows, tracking operational parameters, and validating long-term sequestration performance. The Role of Data Fidelity in Biochar Carbon Accounting Accurate carbon accounting begins with data fidelity. Biochar generation is governed by thermochemical transformation, and even slight variations in feedstock moisture, reactor temperature, or residence time can alter carbon yield. A sophisticated dMRV architecture mitigates these variances by capturing high-granularity data directly from the biochar machine control system. Short data pulses—temperature peaks, pressure fluctuations, or syngas volume anomalies—are complemented by long-interval metrics, such as cumulative biochar output and ash ratio. Together, they create a defensible audit trail. dMRV platforms elevate these raw measurements into structured datasets using metadata such as timestamps, sensor calibration records, and process batch identifiers. This allows project developers, validation bodies, and registries to corroborate carbon retention claims with mathematical precision. Process-Level Tracking Within Modern Pyrolysis Infrastructure A biochar CDR project hinges on understanding every stage of thermochemical conversion. Integration between the digital system and the biochar pyrolysis machine fosters predictive analytics and near-real-time oversight. Key process parameters typically captured include: Inlet feedstock composition: lignocellulosic ratios, particle density, and contamination levels. Thermal trajectory: reactor ramp-up curves, sustained high-heat phases, and cooldown profiles. Syngas composition: hydrogen concentration, methane traces, and condensable tars. Biochar output characteristics: carbon fraction, aromaticity (H/C_org ratio), and pH value. These datapoints feed into carbon permanence calculations. Because biochar stability depends on its aromatic carbon fraction, having precise chemical signatures ensures durability forecasts—often modeled over centuries—are evidence-based rather than speculative. Digital Verification and Chain-of-Custody Beyond quantifying carbon, a biochar CDR project must prove that generated material is transported, applied, or stored according to protocol. dMRV extends into a chain-of-custody system that may include tamper-evident QR codes, GPS-anchored delivery logs, or photo-verified deployment events. Such tracking prevents double-counting and strengthens the integrity of carbon credit issuance. When biochar is dispersed onto soils, integrated geospatial layers reveal application zones, tonnage distribution, and compliance with agronomic thresholds. Lifecycle Modeling and Emissions Reconciliation Lifecycle assessment (LCA) is indispensable for discerning net carbon removal. A robust dMRV system includes automated reconciliation workflows that incorporate upstream and downstream emissions, such as: Feedstock harvesting and preprocessing. Transportation to the pyrolysis plant. Energy consumption during thermochemical conversion. Post-processing, packaging, and movement of biochar. Digital reconciliation ensures that every emission source is accounted for before final net-removal figures are generated. This prevents inflated claims and aligns with emerging international standards for CDR disclosures. Integrating Remote Sensing and Edge Devices Many contemporary dMRV solutions employ remote sensing for environmental verification. Multispectral imagery, drone-assisted inspections, and satellite analytics provide corroborating evidence of land-use patterns, biomass availability, or soil application extents. At the facility level, edge devices mounted on conveyors, reactors, and storage silos reduce manual input error. They preload verification data directly into encrypted ledgers, enabling continuous monitoring without operational downtime. Automation, Transparency, and Audit Readiness A biochar CDR project must maintain perpetual audit readiness. Automated data pipelines significantly reduce the risk of human-induced discrepancies. Immutable logs—often maintained via distributed ledger technology—ensure traceability across every process node. Transparency is reinforced through standardized reporting templates that present auditors with concise, well-structured evidence: parameter trends, calibration cycles, non-conformance alerts, and remediation actions. This systematic approach enhances market trust and accelerates credit issuance cycles. Scalability Considerations for Global Deployment Scaling biochar-based CDR demands interoperability. dMRV systems should support modular expansion, allowing additional pyrolysis plant units, feedstock streams, or regional hubs to be integrated without data fragmentation. Open APIs, machine-readable reporting formats, and harmonized taxonomies ensure that multiple facilities can align under a unified verification architecture. This is particularly critical when operating across jurisdictions with divergent environmental regulations or registry requirements. Future Trajectories in Biochar dMRV Technological evolution continues to refine the rigor of biochar CDR monitoring. Advanced spectroscopic tools may soon enable continuous carbon-stability profiling during production. Machine-learning models could predict reactor anomalies or optimize carbon yield based on historical trends. As regulatory frameworks mature, dMRV systems will likely incorporate standardized carbon integrity metrics, automated third-party verification triggers, and cross-registry synchronization for global transparency. Advancing High-Integrity Removal Through Rigorous Digital Infrastructure A biochar CDR project anchored in a precise, tamper-resistant, and scalable dMRV system is positioned to deliver trustworthy carbon removal outcomes. Data-centric governance enhances credibility, optimizes reactor efficiency, and substantiates permanence claims. The convergence of thermochemical engineering and digital verification practices forms the backbone of reliable biochar deployment, enabling stakeholders to contribute meaningfully to long-term atmospheric carbon reduction.